Tender news

Tender news

SPA catalyst information

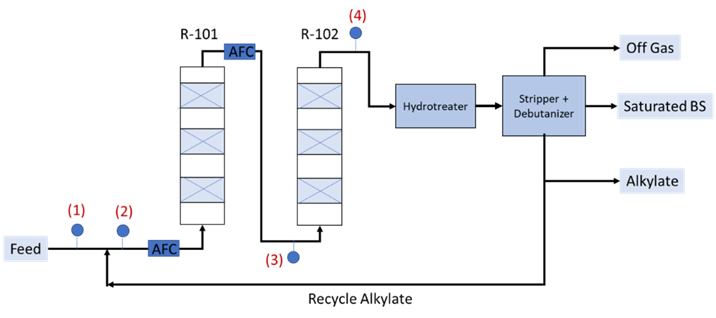

Polymerization Catalyst (Solid Phosphoric Acid Catalyst – SPA Catalyst) is used in Poly reactor in polymerization section of in-direct Alkylation unit. The polymerization is the chemical process by which two or more molecules combine to form one larger molecule. The polymerization reaction of two molecules of butene over SPA catalyst produces octane, which is the desired product for gasoline blending of the Poly reactor.

NSRP SPA lead reactor (R-101) feed properties and operating conditions:

| Feed composition | Typical concentration |

| C3, mol% | 0.14 |

| iC4, mol% | 21.25 |

| nC4, mol% | 5.06 |

| IC4=, mol% | 25.60 |

| 1C4=, mol% | 12.01 |

| Cis-C4=, mol% | 15.13 |

| Trans-C4=, mol% | 20.82 |

| C5+, mol% | <0.97 |

| Total, mol% | 100 |

| Feed contaminant | Typical concentration |

| Acetone, ppmwt | Average 250-300 (during one NRU cycle) (Peak 500-800 @ the end of NRU adsorption) (*) |

| Diene, ppmmol | 400 |

| Nitriles, ppmwt | <3 |

| Acetaldehydes, ppmwt | 7 |

| Sulfur, ppmwt | <20 |

(*) The acetone in feed can be used for SPA catalyst hydration and its content normally can vary from 0 to peak 500 – 800 ppmwt depending on upstream absorber (NRU) cycle in each sequence 24 – 72 hours.

| Feed composition | Typical concentration |

| C3, %wt | 0.03 |

| iC4, %wt | 7.46 |

| nC4, %wt | 2.46 |

| IC4= and 1C4=, %wt | 25.60 |

| Cis-C4=, %wt | 5.01 |

| Trans-C4=, %wt | 7.17 |

| C5+, %wt | 0.69 |

| Alkylate | 51,58 |

| Parameter | R-101 (typical) |

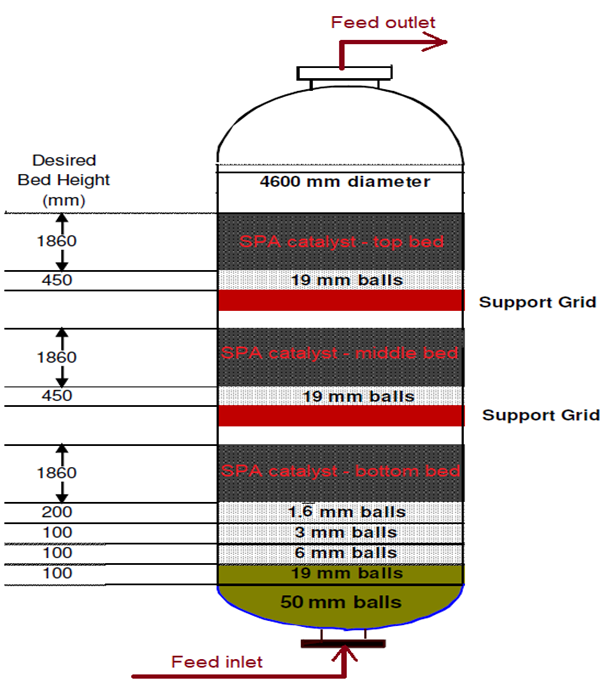

| SPA reactor catalyst bed (batch) | 03 |

| Fresh feed rate, MT/day (at design 100% capacity) | 85 |

| SOR inlet temperature, oC | 110 |

| SOR outlet temperature, oC | 165 |

| EOR inlet temperature, oC | 150 |

| EOR outlet temperature, oC | 185 (max) |

| SPA Reactor inlet pressure kPag | 3300-3800 |

| SPA Reactor outlet pressure kPag | 3100-3600 |

| SPA each catalyst batch dP kPag | 25 – 70 (max: 90) |

If your company is interested in those procurement packages, please fill in and the complete questionnaire below then send email to giang.pt@nsrp.com.vn by 19th Jun 2024 at the latest. For the avoidance of doubt, this notice does not constitute any contractual offer, binding promise or guarantee of business by NSRP.

Part 1. Survey questionnaire

QUESTION 1: Please provide your SPA catalyst general information: product and chemical name, CAS number, formula, shelf life.

QUESTION 2: Please provide technical information which is related to your SPA catalyst: material safety data sheet (MSDS); product specification (including typical chemical properties and catalyst composition) and certification of analysis (COA)

QUESTION 3: Please provide operating condition for your SPA catalyst at start of run (SOR) and end of run (EOR) operation (including limitation if any): inlet and outlet SPA reactor temperature; SPA reactor pressure; SPA catalyst reaction phase in the reactor; each catalyst bed pressure drop at SOR and EOR.

QUESTION 4: Please provide your catalyst performance for I-butene conversion; n-butene conversion (wt%); light alkylate product RON number.

QUESTION 5: Please provide the list of current their customers list who are using their products including unit name; actual capacity; feed properties; operating data and catalyst performance.

Không thể sao chép